Hello, I have some questions about repairing stripped plastic screw holes. What are the safest materials to use? Are there health risks with common adhesives? How can I avoid exposure to harmful fumes? What precautions should I take during repair?

How to fix stripped plastic screw hole safely while minimizing health risks and maintaining material integrity?

Related Encyclopedia

- 83873-16-9

- C22H28O4

- 356.46

- All (0)

- China (0)

- (0)

- 51252-84-7

- C3H4O2

- 72.06270

- All (0)

- China (0)

- (0)

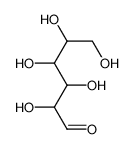

- 25191-16-6

- C6H12O6

- 180.15600

- All (0)

- China (0)

- (0)

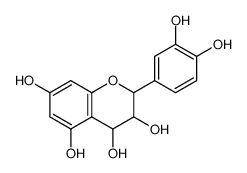

- 27015-21-0

- C15H14O7

- 306.26700

- All (0)

- China (0)

- (0)

- 64742-49-0

- N/A

- 112

- All (0)

- China (0)

- (0)

- 75216-45-4

- C18H11NO3

- 289.28

- All (0)

- China (0)

- (0)

- 64742-94-5

- C9

- 0

- All (22)

- China (4)

- (22)

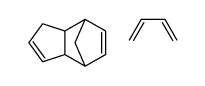

- 49603-39-6

- C14H18

- 186.29300

- All (0)

- China (0)

- (0)

- 29159-23-7

- C7H7NO

- 121.13658

- All (0)

- China (0)

- (0)

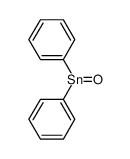

- 31671-16-6

- C12H10OSn

- 288.92000

- All (0)

- China (0)

- (0)

Related Products More >

-

- 9003-55-8

- CNY Request For Quotation

-

- CNY Request For Quotation

-

- CNY Request For Quotation

-

- CNY Request For Quotation

沪ICP备2021018848号-5

沪ICP备2021018848号-5

From a physiological or pharmacological perspective, while this is primarily a mechanical repair, improper fixing methods or use of harmful chemicals during the process could release toxic substances or fumes, which may cause respiratory irritation or allergic reactions if inhaled or contacted, especially in sensitive individuals. Additionally, sharp or loose plastic fragments might cause minor injuries or skin irritation. Ensuring safe handling and proper ventilation during repair is important to minimize these risks.

Clinically, exposure to volatile organic compounds (VOCs) from adhesives or solvents used in repair could exacerbate asthma or other respiratory conditions. People with chemical sensitivities should avoid inhaling fumes and use personal protective equipment such as gloves and masks. If the plastic component is part of medical or childcare equipment, maintaining material safety and avoiding contamination during repair is crucial.

Recommended approaches include using plastic epoxy or specialty fillers designed for plastic repair to rebuild the screw hole. These materials bond chemically to the plastic and cure to a hard, durable finish, restoring the threads’ function. Alternatively, inserting a small threaded metal or plastic insert after enlarging the hole can provide a stronger, more reliable fix. Avoid harsh solvents that can degrade the plastic further or release harmful vapors.

For patients or caregivers, following safety guidelines when handling repair compounds and ensuring well-ventilated areas can reduce health risks. If uncertain, consulting a professional for repairs or replacement might be safest.

One common repair method uses epoxy resin, a thermosetting polymer formed from epoxy monomers and curing agents. When mixed, these components undergo a chemical reaction called cross-linking, where covalent bonds form between polymer chains, creating a hard, durable matrix that adheres strongly to the plastic surface. The polarity of epoxy molecules and the plastic substrate affects adhesion; similar polarity improves bonding due to stronger intermolecular forces like hydrogen bonding or Van der Waals interactions.

The repair process involves filling the stripped hole with epoxy, which after curing restores the shape and provides a new threaded surface. The epoxy’s chemical stability and covalent bonding network ensure the fix resists mechanical stress and environmental factors like moisture and temperature changes. Sometimes, specialized plastic fillers or inserts made from compatible polymers are used; these rely on similar chemical structures and bonding types to integrate seamlessly.

From an experimental or industrial viewpoint, preparing the damaged area by cleaning and lightly roughening improves chemical bonding by increasing surface area and removing contaminants that interfere with adhesion. Understanding polymer polarity and compatibility guides the choice of repair material to maximize durability.

In biological applications, polymer stability and biocompatibility are crucial; for example, some plastics used in medical devices can be repaired with biocompatible epoxies to avoid adverse reactions.

People often make missteps here. One big mistake is forcing a larger screw into the stripped hole, thinking it’ll “grab better.” But that can split the plastic, making the problem worse. Others use too much glue, which oozes out and gums up the works, or they rush the drying time, so the fix falls apart when they insert the screw. And some try to “re-thread” the hole with a screwdriver, twisting it around to create new grooves, but that usually just makes the plastic more worn and doesn’t hold.

For a home-friendly fix, start with the simplest solution: toothpicks and wood glue (yes, even on plastic). Break a few toothpicks so they fit into the stripped hole—you want enough to fill the space without forcing them. Dab a little wood glue on the toothpicks, push them into the hole, and let them sit for 10-15 minutes. Once the glue is tacky, trim the excess toothpicks flush with the plastic using a utility knife. Then, re-drill a small pilot hole (smaller than the screw) and insert the screw—it’ll grip the toothpicks, which now act like new threads. This works great for light-duty plastic, like in picture frames or storage bins.

For slightly larger holes or harder plastics, try a plastic wall anchor (the small, cone-shaped ones used for drywall). Choose an anchor that’s just a bit bigger than the stripped hole. Tap it gently into the hole with a hammer—don’t hit too hard, or you’ll crack the plastic. Once it’s flush, the screw will twist into the anchor, which expands to hold tight. This is good for things like plastic shelving or tool cases.

If the plastic is thin or flexible, a drop of super glue (gel type, to avoid running) can help. Apply a tiny amount around the stripped hole, let it dry for 30 seconds (just enough to get tacky), then screw in the screw while the glue is still slightly soft. The glue fills the gaps and hardens around the screw, creating a bond. Be careful not to use too much—excess glue can make the screw stuck permanently.

For all fixes, let any glue dry fully before putting pressure on the screw—rushing this step is why most repairs fail. And if the plastic is really cracked around the hole, it might be time to replace the part, but for most everyday stripped holes, these tricks work. With a little patience, you can get that screw to hold tight again without buying expensive tools.

Imagine you’re trying to hang a shelf, but the screw just spins uselessly in the wall because the hole’s too big. Frustrating, right? Now picture that wall is made of plastic—like a toy, laptop case, or old gadget. My roommate once had a gaming controller with a stripped battery compartment screw hole. He tried jamming in bigger screws, but it just cracked the plastic more. Then he used a toothpick dipped in superglue… and voilà! The screw held tight.

Here’s the science: Plastic screw holes strip when the threads (the grooves the screw fits into) wear down or the hole widens. Unlike metal, plastic doesn’t “heal”—once the threads are gone, they’re gone. But you can create new threads by filling the hole with a material that hardens and provides grip. The key is choosing a filler that matches the plastic’s flexibility (rigid epoxy for hard plastics, softer adhesives for flexible ones).

Here’s how to fix it step-by-step:

Clean the hole: Use a toothpick or small drill bit to remove any plastic debris or old adhesive. A clean hole helps the filler stick better.

Pick your filler:

Toothpicks + glue: For tiny holes, dip a wooden toothpick in wood glue or superglue, insert it into the hole, and snap it off flush. Let it dry, then drill a new pilot hole.

Epoxy putty: Knead a two-part epoxy (like J-B Weld PlasticWeld) and press it into the hole. Shape it to mimic the original threads, then let it cure (check the package for time).

3D-printing filament: Melt a short piece of PLA or ABS filament with a soldering iron and press it into the hole. Once cool, drill a new pilot hole.

Test the fit: After the filler dries, gently screw in the original screw. If it’s still loose, add more filler or try a slightly larger screw (but don’t overdo it!).

Pro tip: Prevent future stripping by using screws with a “thread-forming” design (like self-tapping screws) or adding a drop of thread-locking adhesive (like Loctite Blue) to the screw before inserting it. This creates a tighter bond without damaging the plastic!

Bottom line: Stripped plastic screw holes aren’t the end of the world. With a little glue, putty, or creativity, you can rebuild those threads and save your project from the trash bin. Now go fix that broken toy/laptop/shelf and feel like a DIY hero! ??