Hello, I’d like to ask if plastic materials can be powder coated. What types of plastics work best with this process? How does powder coating adhere to plastic surfaces, and are there any special preparations needed? Is powder coating on plastic durable compared to metal?

Can Plastic Be Powder Coated? Understanding the Process and Possibilities

Related Encyclopedia

- 51252-84-7

- C3H4O2

- 72.06270

- All (0)

- China (0)

- (0)

- 25191-16-6

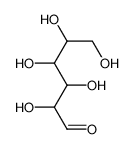

- C6H12O6

- 180.15600

- All (0)

- China (0)

- (0)

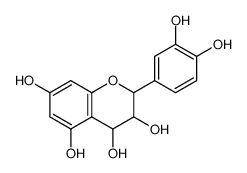

- 27015-21-0

- C15H14O7

- 306.26700

- All (0)

- China (0)

- (0)

- 125720-21-0

- C47H74N16O10

- 1023.19

- All (0)

- China (0)

- (0)

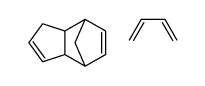

- 49603-39-6

- C14H18

- 186.29300

- All (0)

- China (0)

- (0)

- 29159-23-7

- C7H7NO

- 121.13658

- All (0)

- China (0)

- (0)

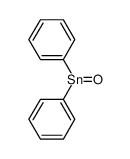

- 31671-16-6

- C12H10OSn

- 288.92000

- All (0)

- China (0)

- (0)

- 12260-12-7

- F3H2-

- 59.01110

- All (0)

- China (0)

- (0)

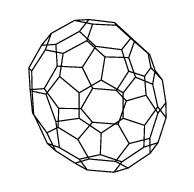

- 145954-03-6

- C78

- 936.83500

- All (0)

- China (0)

- (0)

- 72380-68-8

- C12H10FeSi

- 238.13800

- All (0)

- China (0)

- (0)

Related Products More >

-

- 9003-55-8

- CNY Request For Quotation

-

- 7446-19-7

- USD 10.0000

- 25kg

-

- 75-13-8

- CNY 180000.0000

- 1ton

-

- USD 340.0000

- 200kg

沪ICP备2021018848号-5

沪ICP备2021018848号-5

Thermoplastics like polypropylene or polyethylene generally have lower melting points, which makes them harder to powder coat directly since the heat might deform the plastic. However, certain plastics with higher heat resistance, like some engineered thermoplastics, can be powder coated successfully.

To make powder coating stick well to plastic, special surface treatments are needed. This often involves cleaning and then applying a chemical primer or pre-treatment that helps the powder adhere. Without proper preparation, the powder coating might peel or flake off.

The result is a durable, colorful, and protective layer that can resist scratches and fading, much like on metal. Powder coating plastics is popular in industries where aesthetics and protection are both important, such as automotive parts or consumer goods.

In summary, powder coating plastic is possible but requires the right kind of plastic and special preparation to ensure a lasting finish. It offers an excellent protective and decorative coating when done correctly, but not all plastics are suitable for this method.

Most plastics are thermoplastic or thermoset materials. Thermoplastics like polyethylene or polypropylene tend to have relatively low melting points and can deform or melt during the high-temperature curing stage of powder coating, typically around 160–200°C. This thermal limitation means that many common plastics are not inherently suitable for conventional powder coating processes without modification or special handling. Conversely, engineering plastics such as polycarbonate or certain high-temperature thermoplastics exhibit higher heat resistance and thus are better candidates for powder coating.

Another key consideration is surface energy. Plastics generally have low surface energy, leading to poor adhesion of coatings without proper surface preparation. Techniques such as corona treatment, plasma treatment, or chemical primers are employed to increase surface energy and promote strong bonding between the plastic substrate and the powder coating. This pretreatment is essential to ensure durability and prevent delamination or peeling under mechanical stress or environmental exposure.

In practical scenarios, powder coating plastics is commonly used in automotive parts, consumer electronics, and outdoor furniture, where a durable, aesthetic finish is required. For example, powder-coated automotive bumpers or plastic housings can offer enhanced UV resistance, chemical resistance, and scratch protection compared to uncoated plastics.

Overall, powder coating plastic is feasible but requires selecting appropriate plastic types, employing surface treatments, and optimizing curing conditions to balance adhesion, mechanical integrity, and finish quality. Understanding these principles allows manufacturers to expand the benefits of powder coating beyond metals to a wider range of plastic components.

Powder coating typically involves three stages: **electrostatic application**, where powder particles adhere to a grounded substrate via electrostatic attraction; **melting**, where the powder flows into a uniform layer; and **curing**, where cross-linking reactions harden the film. The critical challenge with plastic lies in the **curing temperature**, which for most powder coatings ranges from 160°C to 200°C. Most plastics, however, have low glass transition (Tg) or melting points (Tm): polyethylene (PE) melts at 105–130°C, polypropylene (PP) at 130–170°C, and polystyrene (PS) at 240°C but softens significantly above 100°C. Exposing these plastics to standard curing temperatures causes deformation, warping, or degradation, as the heat disrupts their polymer chains and weakens intermolecular forces. This thermal mismatch has historically limited powder coating to high-temperature materials like metals.

Yet, **high-performance plastics** with elevated thermal stability can withstand powder coating conditions. Polymers such as polyamide-imide (PAI), polyphenylene sulfide (PPS), and liquid crystal polymers (LCPs) have melting points exceeding 250°C, allowing them to endure curing temperatures without structural damage. For example, PPS, a semi-crystalline polymer with a Tm of ~280°C, maintains its rigidity at 200°C, making it compatible with standard powder coatings. These plastics are used in industrial applications (e.g., automotive underhood components) where both heat resistance and a durable finish are required. Their ability to retain shape under heat stems from strong covalent bonds and high crystallinity, which resist chain mobility even at elevated temperatures.

Another key factor is **surface conductivity**, as electrostatic powder application requires the substrate to hold a charge. Most plastics are electrical insulators, meaning they cannot ground properly, leading to uneven powder adhesion or “back ionization” (where accumulated charge repels incoming powder). To address this, plastic surfaces can be treated to enhance conductivity. Methods include **plasma etching**, which introduces polar functional groups (e.g., hydroxyls) that improve charge retention, or applying a conductive primer (e.g., carbon-filled epoxy) that creates a grounded layer. These treatments bridge the gap between the plastic’s insulating nature and the electrostatic requirements of powder coating, enabling uniform particle deposition.

Adhesion is also critical, as the powder coating film must bond securely to the plastic surface. This relies on **mechanical interlocking** and **chemical compatibility**. Plastics with textured surfaces (e.g., molded-in ridges) provide micro-anchors for the molten powder, enhancing mechanical bonding. Chemically, the powder coating’s polymer (e.g., epoxy, polyester) must interact with the plastic’s functional groups. For instance, epoxy-based powders bond well to PAI, which contains amine groups, via hydrogen bonding, while polyester powders adhere to PPS through van der Waals forces. In contrast, non-polar plastics like PE or PP lack reactive sites, making adhesion poor even with surface treatment, further limiting their suitability.

Innovations in **low-temperature powder coatings** have expanded possibilities for heat-sensitive plastics. These formulations cure at 120–150°C, achieved by using reactive diluents or catalysts that lower the cross-linking temperature. While they sacrifice some durability compared to high-temperature coatings, they can be applied to plastics like ABS (Tg ~105°C) or polycarbonate (PC, Tg ~145°C) without causing deformation. For example, a low-temperature epoxy-polyester hybrid powder can cure at 130°C, allowing it to coat PC automotive trim, providing corrosion resistance and a glossy finish. However, these coatings require precise control of curing time and temperature to avoid under-curing (poor adhesion) or overheating (plastic damage).

Misconceptions about powder coating plastic often stem from overgeneralizing plastic types. A common myth is that “no plastic can be powder coated,” but high-temperature plastics like PPS or PAI have long been used in industrial settings with this process. Conversely, assuming all plastics can be coated with low-temperature formulations ignores the trade-offs in durability and the continued incompatibility of low-melting-point polymers like PE. Another误区 is equating powder coating to spray painting, which uses solvents and can adhere to a wider range of plastics; powder coating’s thermal and electrostatic requirements make it far more selective.

In professional fields like automotive engineering and industrial manufacturing, powder coating plastic is valued for its durability, environmental benefits (no volatile organic compounds), and uniform finish. Engineers select plastics and coatings based on thermal compatibility, using **differential scanning calorimetry (DSC)** to measure a plastic’s Tg and Tm, ensuring it exceeds the coating’s curing temperature. They also use **adhesion testing** (e.g., cross-hatch or peel tests) to verify bond strength, critical for applications like electrical enclosures or outdoor equipment. Material scientists continue to develop new plastics and coatings, such as graphene-reinforced polymers with higher thermal stability, expanding the range of powder-coatable substrates.

In summary, plastic can be powder coated, but success depends on matching the plastic’s thermal stability to the coating’s curing requirements, ensuring electrostatic compatibility, and achieving adequate adhesion. High-temperature plastics like PPS or PAI work with standard coatings, while low-temperature formulations enable coating of more common plastics like ABS or PC, albeit with trade-offs. This process, rooted in polymer science and coating technology, offers a durable, eco-friendly finish for select plastic components, dispelling the myth that powder coating is exclusive to metals.

Plastics, as thermosetting or thermoplastic polymers, exhibit fundamentally different thermal behaviors compared to metals. Thermoplastics (e.g., polyethylene, polypropylene) soften when heated and harden when cooled, making them vulnerable to deformation at the high temperatures required for powder coating curing. Thermosets (e.g., epoxy, polyester), which cure irreversibly into a rigid structure, can theoretically withstand higher temperatures but often lack the surface energy needed for powder adhesion without pre-treatment. This thermal sensitivity necessitates two key adaptations: the use of low-temperature curing powders and the modification of plastic surfaces to enhance adhesion. Modern powder formulations now include acrylic or hybrid resins that cure at temperatures as low as 120–140°C, reducing the risk of thermal degradation in heat-sensitive plastics like ABS or polycarbonate.

Surface chemistry plays a pivotal role in achieving adhesion between powder and plastic. Unlike metals, which have inherently high surface energy, plastics are non-polar and hydrophobic, causing powder particles to bead up rather than spread uniformly. To overcome this, plastics undergo pre-treatment processes such as flame treatment, corona discharge, or plasma etching, which introduce polar functional groups (e.g., hydroxyl, carbonyl) onto the surface. These groups increase surface energy, enabling the powder to “wet” the substrate and form mechanical interlocks during curing. Additionally, primers containing adhesion promoters—such as silane coupling agents or acrylic polymers—can be applied to create chemical bridges between the plastic and the powder, further improving bond strength.

The physical mechanisms of powder coating on plastics involve electrostatic deposition followed by thermal fusion. During deposition, charged powder particles are attracted to the grounded plastic substrate, forming a uniform layer. Upon heating, the powder melts and flows, filling microscopic surface irregularities to create a smooth, continuous film. As the coating cools, it solidifies into a durable, wear-resistant finish with properties like corrosion resistance, UV stability, and aesthetic appeal. For plastics, this process must be carefully controlled to avoid warping or shrinkage; infrared or convection ovens with precise temperature gradients are often used to ensure even curing without overheating.

Practical applications of powder-coated plastics span multiple industries. In automotive design, powder-coated plastic components like mirror housings or grilles offer a lightweight, corrosion-resistant alternative to metal, improving fuel efficiency and design flexibility. Consumer electronics benefit from the scratch resistance and vibrant colors of powder coatings on plastic casings, enhancing durability and user appeal. In medicine, powder-coated plastic devices (e.g., surgical instruments, housing for diagnostic equipment) provide a biocompatible, easy-to-clean surface that meets stringent hygiene standards. The process also aligns with sustainability goals, as powder coatings produce minimal volatile organic compounds (VOCs) compared to liquid paints, reducing environmental impact.

The broader significance of powder coating plastics lies in its potential to redefine material usage and product lifecycle management. By enabling durable, high-performance finishes on lightweight plastics, it reduces the need for heavier, resource-intensive metals in many applications. This shift supports trends like electrification (e.g., in electric vehicle components) and miniaturization (e.g., in portable medical devices), where weight and space are critical. Moreover, the ability to recycle powder-coated plastics—though challenging due to the coating’s thermal stability—is an area of active research, with innovations in chemical stripping and mechanical separation pointing toward a more circular economy.

In summary, while powder coating plastics demands careful consideration of thermal, chemical, and physical factors, technological advancements have made it a viable and increasingly common practice. Its integration into diverse fields underscores the importance of interdisciplinary collaboration between material scientists, chemists, and engineers, driving innovation that balances performance, sustainability, and cost-effectiveness. As the demand for lightweight, durable materials grows, powder coating plastics will continue to play a pivotal role in shaping the future of manufacturing and design.